Blog

How supply chain issues have impacted the price of Wood and Steel

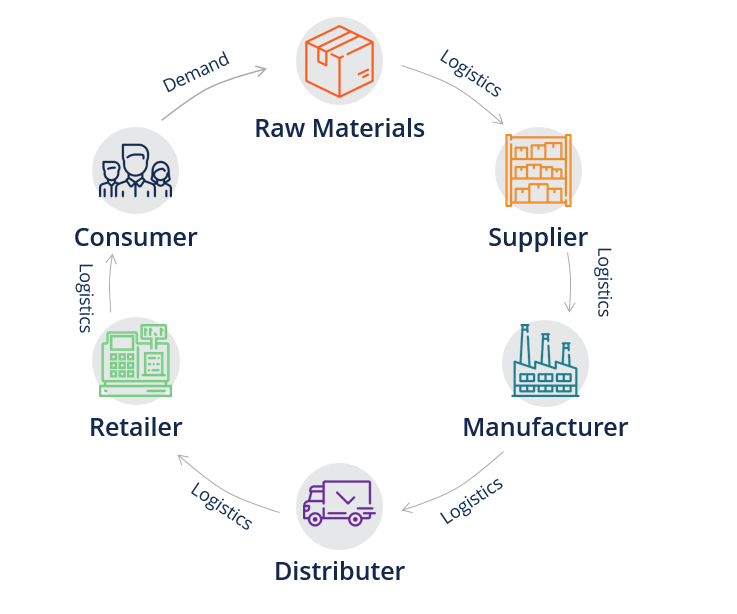

Supply chain problems persist, factory floor capacity for steel production remains diminished, consumer needs and spending patterns have changed, and the biggest factor—a once-in-a-century pandemic—remains a potent global force whose resurgence is uncertain and one whose remaining effects have yet to be realized.

The pandemic hit manufacturing hard. One of the first shockwaves stemmed from government categorization of essential and non-essential businesses. Some manufacturers in the latter category were forced to completely shut down or drastically reduce production. Others deemed essential were stretched to the limit trying to keep up with demand. As the pandemic wore on, consumer needs and spending patterns also drastically changed, causing further disruption and response—some experiencing unprecedented demand and success, while others struggled to remain relevant.

The reason

Low interest rates, to nurture the fragile economy, led to a huge boom in the building industry, which quickly sopped up the excess lumber idling in yards because of the pandemic onset. This has led to the demand for lumber increasing rapidly over the past few months, supply has not been able to catch up, resulting in an increase in lumber’s cost to the consumer of 340% or more locations.

Steel is another commodity that has experienced substantial price increases. The state of the steel market is a by-product of several domestic and international events. This is not a Swivel Solutions -only issue, it is more of a global supply problem that every business and every consumer is facing.

The effects

Normal fluctuations of steel prices are around a penny or two (plus or minus) month-over-month, depending on what is taking place in the market.

- August, September, and October 2022: The price of steel increased about+7.5%

- December 2020: The steel price had a major uptick of about +20% from August 2022.

- January 2022: The price of steel had jumped up +37% from August 2022.

- February/March 2022: The price of raw, bare steel is up over +75% from August 2022.

Now that you have some background on the current state of the steel supply shortage and price increase, you might be asking yourself what this means for you, the consumer.

To keep it as simple as possible: It means there is extraordinarily little steel to be had and what can be had is pricey.

Toolboxes are expensive because they are a type of security gadget to protect your tools. For this reason, they are made using high-quality unbreakable materials that come at a premium cost. Most of the toolboxes are manufactured using high-quality steel and this material is even more expensive to buy for the reasons shared above.

Toolboxes are shipped to customers and sales outlets on wooden pallets, which are affected by the price increase and shortage of lumber.

Clamca Toolbox Distributors and Swivel Storage Solution have not increases the prices of the toolboxes in 9 years, but with the increase above, we have put out a new price list. We the heavy duty steel workbench that serve as 2in1 workbench with swivel drawers, the price support the high quality of the product and our ability to stand behind our limited life time warranty.

Call us or email us to a quote to outfit your garage, work truck, work van or your work station at your factory.

https://toolboxdistributors.com/shop